Building Technologies that make Housing Affordable; EPS Panels

With a high housing deficit in Kenya, alternative building technologies enable more people to own homes at lower costs without compromising on comfort or safety.

Why it is Expensive Building a House in Kenya

The process of acquiring land to the actual owning of a house in Kenya is a tedious exercise. The prices of land, dealing with brokers and risks of being defrauded, the legal processes, the approval of the development projects and the subsequent costs of construction make it so expensive to build.

For this reason, semi-permanent houses have been the only alternative means for survival when it comes to shelter. Houses build with mud, corrugated iron sheets and sun-dried bricks provide alternatives homes but with these, safety and comfort are compromised.

The affordable housing program by the government makes houses affordable by eliminating the above processes but the programme has so far only been rolled out in Nairobi.

Expanded Polystyrene Panels

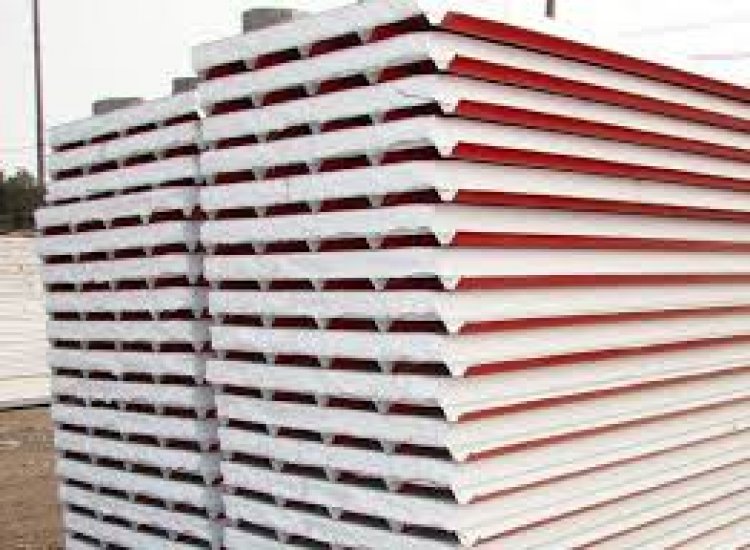

Most often the expanded polystyrene panels are confused with Styrofoam. Styrofoam is the one used as a packaging material, like that of TVs. Styrofoam is made from extruded polystyrene while the EPS is made of expanded polystyrene. The EPS panels are the ones used in construction.

(EPS Panels)

The EPS are made in form of large blocks, unlike the traditional small bricks. The blocks are reinforced with concrete slabs at the sides. With this building material, the use of cement is minimized and also the labour as the construction mainly involves making the house pillars and fixing the EPS material into building blocks. The materials are manufactured in factories then transported to the construction site where they are assembled, hence the name prefabricated houses.

The advantages of this building material are:

- It is non-biodegradable- this means it will not decay and cause destruction.

- It is soundproof

- It regulates temperature- the materials are insulators and the room temperature will not be affected by the temperatures outside.

- It is fire resistant

- It saves on time and labour – it takes a shorter time to build a house with this material and less labour force is needed in the construction, all these save on costs, which are reduced by 30-40%

Houses built by EPS look just like brick and mortar houses and they are strong and durable. This technology has been in existence for a long time, but people don’t accept it readily but its popularity is growing steadily.

The major players in this industry are Koto housing and c-max.

In the next article, we will look at a more advanced panel system; the concrete panel system.